Today in a spare moment I decided to change one of my lower amber marker lights. Did I say spare moment? Silly me as I meant a spare couple of hours or rather, they weren't actually spare but it took a couple of hours to complete a 20 minute job.

The first problem was found when I enlarged the right-hand screw hole. That turned out to be at an angle (Does it really surprise anybody that Carpenter gave up bus manufacturing) which had the knock-on effect of forcing me to move the whole marker light half an inch to the right - closer to the front of the bus. Having done that I could install my 8-32 rivnuts with no problem.Motorhome self build project. Built and designed by one person over the course of about 36 months. The base is a 1994 Carpenter school bus. The end result will be a low energy consumption motorhome.

Pages

Pages

Wednesday, June 30, 2021

One more light, a bunch more problems...

Sunday, June 27, 2021

Another small step.

Today there was a kinda plan to work on something but the day started slowly with my being tired having woken several times in the night, at least one time with acid reflux having eaten too late. The vast majority of the day was spent doing nothing but when the sun went behind clouds in the evening was when things started to happen. It was 92F in the shade, after all.

There was no actual planning involved but I pulled out both of the aluminium sheets then having drilled the requisite 8 holes in the one sheet that had not been drilled - using the first sheet as a template, I set to and removed patches that I'd put over hillbilly holes in the bodywork and put my two new aluminium panels in place.

Tools used today:

- Air compressor

- Air hammer

- Air drill

- Air riveter

- Rivets

- Battery drill

- Drill bit

- Step bit

- White spray paint

- 8 x No 10 self-drilling hex-head screws

- Hex driver for the No 10 screws.

- Dynatron caulk

- Old plastic packet

- Old envelope

- Paint thinner.

- Set of kitchen steps

Saturday, June 26, 2021

Just a couple of hours for this light...

Every light replacement has come with its own unique set of challenges from rotted screws to stuck screws and more. This was no different.

Pulling the lens off, it was amazing to find that the screws were barely rusted. The lens, however, was beyond redemption. It was cracked and therefore the cause of water leakage. Out of curiosity I tried fitting the lens from my Harbor Freight clearance light on instead of the cracked lens because frankly the rest of the light was in good shape. The U bracket it was mounted in was very firmly attached with plenty adhesive. Sadly however the Grote base did not accept the Harbor Freight lens. I noticed that was the lens that fell off a few years ago and had to be patched into place with silicone goop. It was time to replace it - way past time.Unscrewing the rusty screws was pretty straightforward as was easing the U bracket off with a pocket knife. From there I did go down some routes that didn't work out and had to be undone before finally getting it right.The first thing was to put the new light in place and unlike yesterday, remembering to put the foam sealing pad behind it. I had to go back to yesterday's light and put the foam pad in place so it was properly weather sealed. Then it was a case of tinning and soldering the wires before using shrink-on insulation.

Next I drilled out the two screw holes and installed a pair of rivnuts. I might go back and redo yesterday's light once I've done the roof vent, the front marker lights and the window covers. I'm still unhappy with yesterday's work and I am somewhat of a perfectionist.

After that I went over the area where the light would be mounted with a nylon brush in my pistol drill followed by spray painting the area. When the paint was almost dry I squeezed on some Dynatron caulk and screwed the new fixture plus the bracket into place and popped the lens back on.

The caulk might get some white paint when it's dry but that'll have to be done with a brush. I have no plans to do this yet. The white paint is to reflect heat to keep the inside cooler. The grey won't add that much to extra heat so it's probably not worth doing.- New lenses and gaskets on 4 turn signal lights

- New lenses and gaskets on both 7" brake lights

- One brake light totally replaced (4")

- Both reversing lights replaced.

- New lenses on all 4 corner markers.

- One headlamp replaced.

- 5 marker lights totally replaced.

- Three amber top markers - these need to be done after replacing the roof vent as I'll be clambering over them to access the roof vent.

- 4 side markers - These can be done from the ground and need to be done after installing the window covers.

Friday, June 25, 2021

5 hours to do one light, seriously?

Today it was time to start the roof level amber marker lights. When I started, I did have a thought that I might get to do both of the roof level side amber markers. How foolish!

Climbing up the ladder with a pocketknife, the lens was easy to pop off the driver's side marker light. That revealed two crosspoint screws that were amazingly in good condition albeit rusty. That was where things began to go sideways - literally.The first screw came out easily enough. The second one was at an angle so the whole light assembly was slightly bowed which probably accounted for the leaks on that side of the bus. Anyway, the assembly was removed and the area prepared with a brush in the pistol drill then primer then white paint.

The second screw broke the Milwaukee screwdriver bit.

Fixing the crooked screws was the first priority so a new hole was drilled. That showed why the holes had been drilled as they were. The new hole was over a roof support beam. It was necessary to drill into that to put a self-drilling screw. There was no chance of putting a rivnut in that hole so the rivnuts were left out of the equation this time.

Thinking about it, it was probably a mistake to use the hole because there's a slight gap between the roof skin and the support. It might have been better to shift the light half an inch up or down and forward. It might even have been a good idea just to put a steel plate over the existing holes and rivet that and to put the light in a different place. It only has to be as close as possible to the center.

I'll have to revisit this light anyway because I forgot to include the foam gasket with which it was supplied. I might just unscrew it, slap some caulk between the light and the aluminium bracket and leave it at that.

Given the fact each light seems to come with innumerable issues that have to be resolved, these lights will take a while longer. I imagine the center light on the other side will be a complete day. The three at the front should be able all to be done simultaneously.

Tomorrow should be the time for the second middle light to be changed. Following that it'll be time for the roof vent. Then the front 3 lights then the window plating followed by the last 4 marker lights that can be accessed from the ground. After that it'll be the 2nd battery, brakelines, tires and the wiper mount. Following that, some small internal wiring issues need to be resolved.

Thursday, June 24, 2021

Bulb grease to the rescue!

After struggling and failing to remove the old light unit that I was struggling with last time, I left it in place and refurbished it. The problem was the bottom screw was seized rock solid and without undoing the paneling inside to whack the back of the screw with a hammer (or indeed a G clamp that suffices for a hammer until I can find my hammer) which was just a lot more work, refurbishing seemed easier.

The first thing done (demonstrated on the spare) was after removing the lens to pop the spring, plastic insulator and wire out of the bulb holder. Then it was a case of rolling up some zinc oxide type sandpaper to fit inside the lamp holder and work it in all directions to sand the rust out of the holder. Needless to say I sanded the little brass end on the connector wire too.Having now cleaned the old bulb holder it was time to put bulb grease inside and to coat all surfaces included the freshly scraped brass contact. With that slathered on liberally it was a simple case of inserting the bulb.Tuesday, June 22, 2021

Not another problem?

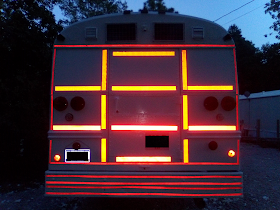

Today was a day of heavy showers so I didn't do an awful lot. I did test the lights on the bus with the main bus battery and the new lights sure look brighter than the old lights. The new turn signals are way better though I didn't really get to see how much better the brake lights are. The new marker lights look phenomenal compared to the old marker lights.

Monday, June 14, 2021

Another blisteringly hot day

Today I realized I had just two of my aluminium rivnuts left. It seems they were 8-32 not 8-24 as I'd thought though oddly they only like specific 8-32 bolts. Despite that I did manage to install my 3rd clearance light.

I think you'll agree - all of those clearance lights had seen better days. The other lights aside from the reversing lights were OK. They just needed new lenses.

Having done 3 clearance lights I now have a further 5 roof level clearance lights and 4 at ground level. I'm trying to get all the roof stuff done as I'm using somebody else's step ladder. I have more than enough amber clearance lights to do the job but need two more red lenses.

Today two things arrived in the post. One is a roll of 3/4 inch amber conspicuity tape that should attach to the gutter. The other is much more intriguing. I ordered a data logger that was advertised on eBay.

This is a rather splendid device that can record temperatures continually over an adjustable period. The write-up was excellent. The reality is somewhat less impressive. It seems to require a CD of software specifically for the device to be used. Thereby hang two problems. First the software is for Windows only and second, my laptop does not have a CD drive. In fact, very few laptops these days do have them.Saturday, June 12, 2021

Another leak...

Today I went to work more on the marker lights. The marker light started yesterday was completed using a pair of rivnuts. That worked well. It was all sealed with more of the magic seam sealant.

Following that it was time to look at the second and third marker lights. The second one which was in the middle looked OK but taking the lens off revealed a grounding screw that was so rusty that its head had dropped off. That left a stump to remove which came out after a few whacks with the pliers and some wiggling. After that it was just a case of enlarging the holes and inserting rivnuts then I had to put it all back together using my magic seam sealant.

Not long after doing the second marker light, it began to pour down with rain. That was an excellent opportunity to check for leaks! Though I could see no water, the inside of the back felt wet. I'm not sure why that should be. The only reason I can think of is that either one of my new light additions was leaking (which I doubt) or the seam that has not yet been redone is leaking. I'll go with that for the moment. It was always my intention to redo the seam anyway.Friday, June 11, 2021

A little progress then a roadblock

The first order of the day was to replace one of the reversing lights and to make sure the other was properly screwed down. That all went fairly smoothly and quickly with my being quite surprised to find the backing on the left reversing light had been a thin hardboard shim. That was very strange. My new lights have built-in foam shim.

Just as I was standing back, admiring my work I heard a vehicle coming down the twisting dirt track that serves as a driveway. As the vehicle slowly approached, it turned out to be the postman or in the particular instance the post lady. She handed me the mail and I knew instantly what was in the box I was handed.

It was the new sticker I'd ordered for the back. Stay back 300 feet. I think my stencil message was probably readable from a greater distance though. I didn't get it quite straight but since the right reflector and right brake light in the lower right quadrant are higher than those on the left, I'm not really bothered.Eventually the cables to which I needed access were free of expanding foam. That xylene foam is a total nightmare. I would recommend anybody considering using it for anything to have their heads examined!

Thursday, June 10, 2021

Counterfeit conspicuity tape

Ebay is a great resource and a great way to find rare and unique products. Sometimes, however, things don't go quite as planned.

These four conspicuity tapes all came from eBay. The amber one on the left is from a vendor called johncatrader2. These are the horizontal lines on the side of the bus. The vertical lines are the middle amber roll. That, came from eBay user powerhigh-usWell, the tape from johncatrader2 is pretty darned good. The powerhigh-us tape does kinda-sorta reflect but it's pretty pathetic by comparison. Interestingly the powerhigh-us tape was a lot thinner and when I peeled it off, it removed none of my recently applied paint. In fact some sections were barely adhering.I think you'll agree, there's little if any difference with the powerhigh-us tape removed. Fortunately I have some good tape left so I'll fill in the gaps.Sunday, June 6, 2021

Crunch!